Common Applications

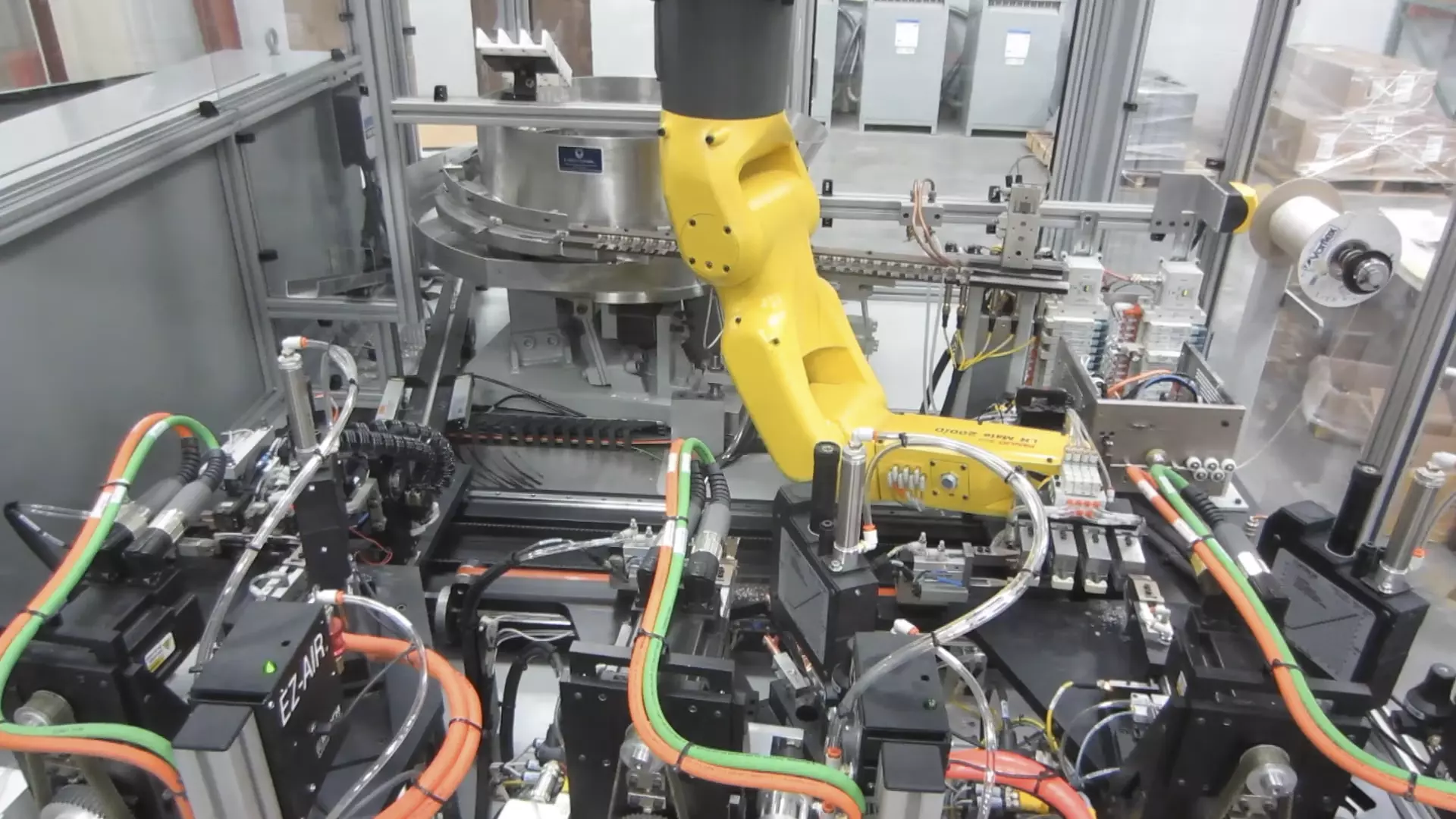

- Large and Small Part Assembly

- Part Feeding and Handling

- Testing

- Leak Testing

- Electrical Testing

- Machine Vision

- Part inspection

- Part Presence

- Go/No-Go Guage

- Measurement

- Defect

- Weight Verification

View our Video Library of automation solutions

Our Value

ISO 9001 certified

ITAR compliant

Established partnerships with all major robotic & sensor companies

Extensive national network to provide localized service and support

75,000 sq.ft. of manufacturing facilities