Common Applications

- Data Collection and Management

- Laser Marking

- Laser Welding

- Conveyance

- Static Management and ESD Compliance

- Automated Soldering

- Automated Dispensing

- Plasma Treatment

- UV and Thermal Cure Adhesive Dispensing

- Leak Testing

- Vision Testing

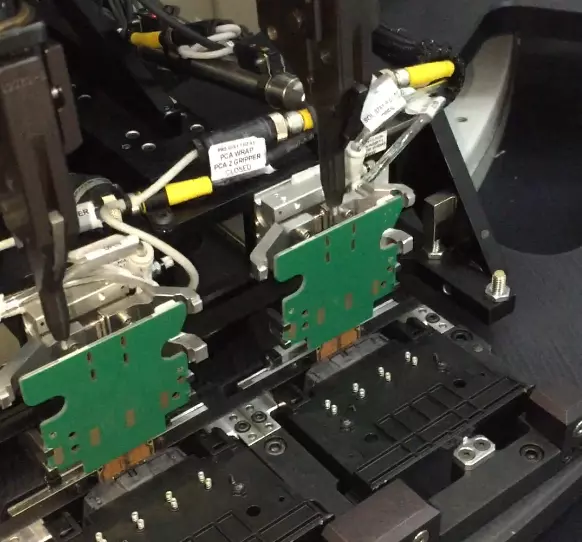

- Electrical Testing

- Small and Large Parts Feeding

- Ink Stamping

- Fluid Interface Design

- Cleanroom Equipment

- Labeling

View our Video Library of automation solutions

Our Value

ISO 9001 certified

ITAR compliant

Established partnerships with all major robotic & sensor companies

Extensive national network to provide localized service and support

75,000 sq.ft. of manufacturing facilities